2D Clay, a Physically

Based Modeling Final Project

Sections

Overview

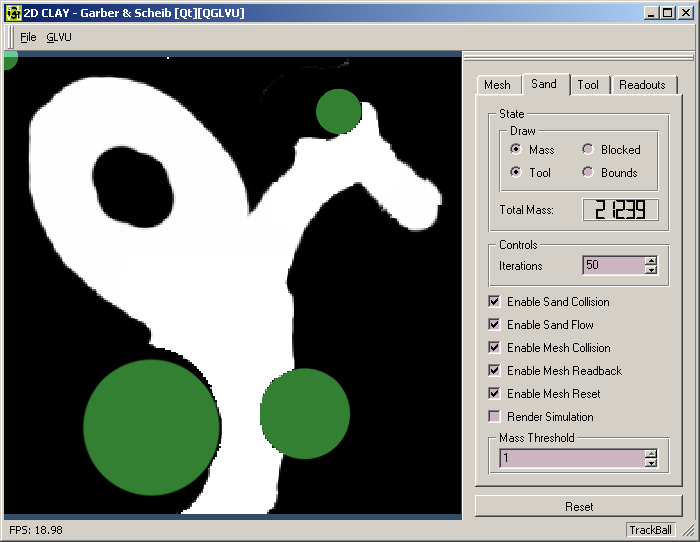

We have created a program to work with

clay, in 2 dimensions. This work is designed to prototype methods for a

3D clay deformation system. Below is a screen shot of our application:

The main part of the window shows clay

(in white) and tools (green). The tools are used to manipulate the clay.

We chose to reconstruct the attributes

of clay with a combination of local and global algorithms. The local algorithm

addresses the fluid like attributes of clay, near the points of tool collision.

Global methods are needed to make large deformations, such as bending an

entire arm.

The local deformations can be seen most

clearly at the top, where the small tool has been dragged against a skinny

arm of the clay. The clay "piles up" in front of the tool due to the local

deformation framework. The global deformations allow the entire arm to

be bent.

Tools and Collision

Detection

In our application tools are represented

as as circles of various sizes that can be moved with the mouse to interact

with the clay.

To compute collision between the clay

mass and the tools we use the standard graphics pipeline. The clay and

tools are rendered, with additive blending, to an off screen buffer (shown

below). The rendering window is set up so that each pixel corresponds to

exactly one cell in our discritization of the clay area. The resulting

image is read back.

For each cell in the clay buffer we can

now query the image to determine if it lies inside a tool, if it contains

clay mass, or both. The cells that both have mass and are inside the tool

are those that cause interactions that change the shape of the clay through

both local and global deformation (described below).

To prevent the tools from interpenetrating

the clay to easily, and give the appearance that the clay is dense, we

use a virtual coupling between the active tool and the mouse. This takes

the form of a damped spring pulling the tool to the mouse pointer location.

This spring is integrated using an Implicit

Euler formulation to allow stability even with high stiffness. To give

the illusion of clay density we add viscous drag, over and above air resistance,

to the tool for each pixel of clay that it intersects. Thus larger tools

push more slowly into the clay that smaller ones, which tend to cut the

clay easily.

Local Deformations

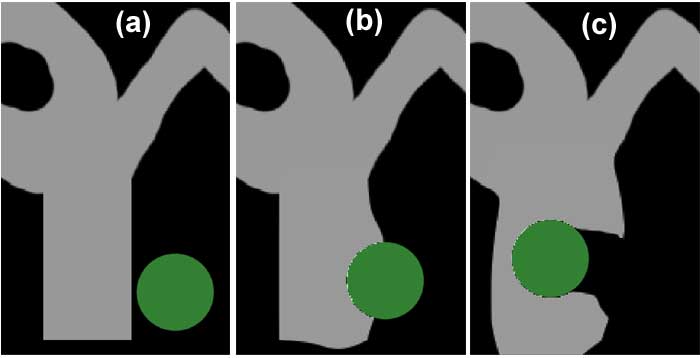

The figure above shows three stages of

a local deformation of the clay when impacted by the tool (green circle).

Notice that the deformation is confined to the area near the tool, and

the upper part of the clay remains still.

To support local deformations of the clay,

we maintain a buffer of the clay mass amount in each cell of a regular

sampling of the clay workspace. In 2D this can be visualized as a mass

texture, in which the brightness of the pixel indicates the mass of clay

in the cell. In the example scenario this sampling of space is done at

256 x 256 resolution. To perform a local deformation of the clay when impacted

by the tool we modify this mass buffer in two ways:

-

project the intersected mass out of the space

occupied by the tool

-

disperse mass so that all cells are within

the density limit

The first step involves traversing the cells

in the local area of each tool. For each cell that contains clay mass,

and is inside the tool, we simply move the cell's mass to the nearest cell

outside the tool along the radial direction. At the end of this step the

cells that border the tool may contain more mass than is allowed by our

density limit.

To fix this situation, we iteratively

traverse the clay cells in a growing region around the tool. Each cell

with excess mass propagates that mass to its neighbors. This propagation

algorithm is based on the concept of Cellular Automata, in the paper Free-Form

Shape Modeling by 3D Cellular Automata by Arata et al.

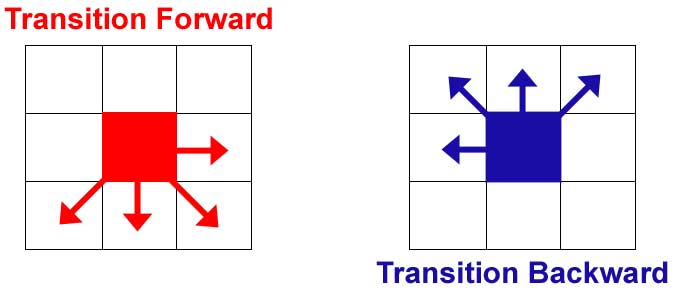

For maximum speed, this propagation is

done in two passes which mimic a bucket brigade. In the Forward pass,

we traverse the array in the forward direction and cells transition their

excess mass to the neighbors ahead of them in the buffer order. In the

Backward pass we traverse the cells in reverse order and cells transition

their excess mass to neighbors behind them in the buffer order.

A transition to a neighboring cell is

not allowed to occur if the neighbor is flagged as blocked by the tool

by our collision detection system. This prevents the mass form flowing

back into the tool.

This transition scheme pushed all excess

mass in one direction, then back in the other, until the excess mass lands

where it can be accepted without overflowing the cell location. This avoids

the situation in which neighboring cells will simply pass excess mass back

and forth to each other with each iteration and thus converge very slowly

to a stable state.

The disadvantage of this approach is that

excess mass can be propagated far in either the forward or backward direction,

instead of settling in a nearby open cell in the opposite direction. This

phenomenon produces unnatural diagonal tendencies in the mass flow. It

also quickly turns the local mass propagation into a global operation than

influences many far away cells.

To address the concern, we use a growing

propagation region that expands outward from the tool and limits the cellular

automata transitions to cells inside the region. This region expands in

a particular direction only if necessary. This expansion is done slowly

as the algorithm iterates ensuring that mass will tend to settle in nearby

open areas rather than those that are far away.

Even with this localizing region our algorithm

is able to disperse all excess mass in the region of a tool in few (10

- 15) iterations.

Global Deformation

Mesh

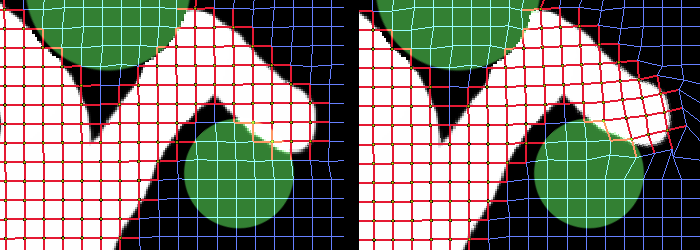

In this set of images, the global deformation

mesh can be seen. This mesh allows a collision at one point to cause deformations

over a large area.

The mesh connects mesh mass points. A

mass point is an intersection of edges of the mesh that is within the clay

mass. Edges which end in at least one mass point are drawn in red.

On the left, the mesh is undeformed. A

tool is colliding with the clay volume. Two types of collisions affect

the mesh:

-

any mass point on the mesh is moved the shortest

distance out of the tool.

-

clay in collision with a tool move is analyzed

to find the shortest distance out. Each mass point on a square containing

clay in collision is moved by the maximum clay penetration.

The combination of these two collision types

provides a way for the mesh to be moved when a tool collides. The first

method handles deep penetrations. The second provides for slight collisions,

where clay is in collision but a mass point is not.

The result of a collision is a few moved

mass points. To enable the entire mesh to respond, an iterative constraint

solver is used.

Each edge is constrained to a constant

length. Each square is constrained to a constant volume. For each iteration,

the mass point constraints are enforced, but doing so affects the neighbors.

Subsequent iterations converge to a solution.

We typically used 50 iterations. This

computation was fast, and the iteration count more than sufficient to relax

the entire mesh. We typically use a 30 by 30 mesh for the entire workspace.

|

|

|